What is 3PL?

Understanding third-party logistics (3PL) is essential for any business looking to optimize its supply chain and fulfillment processes. 3PL refers to the outsourcing of various logistics services such as warehousing, inventory management, and order fulfillment to a specialized third-party provider. This approach allows businesses to focus on their core competencies while leveraging the expertise and infrastructure of a 3PL partner.

Whether you are an e-commerce startup or an established enterprise, learning about 3PL can help you streamline operations, reduce costs, and improve customer satisfaction. In this article, we will explore what 3PL stands for, 3PL benefits, and how it works within the logistics industry.

Understanding 3PL

3PL definition

What does 3PL stand for?

3PL stands for third-party logistics. This term refers to the practice of outsourcing logistics and supply chain management functions to an external provider.

Imagine your favorite online fashion retailer that focuses on designing and marketing clothing and accessories. Instead of handling the logistics of storing, packaging, and shipping their products, the retailer partners with a 3PL provider. The provider takes care of warehousing the fashion items, processing online orders, and delivering them to customers. This allows the fashion brand to concentrate on designing new collections and marketing their products, while the 3PL ensures efficient and timely delivery to fashion enthusiasts.

What is the order process a 3PL follows?

What is 3PL fulfillment?

- Advanced inventory management: Cencora utilizes the latest technology to provide real-time tracking and management of inventory. This ensures accurate stock levels, reduces the risk of stockouts, and helps businesses maintain optimal inventory levels.

- Comprehensive returns management: Cencora provides efficient returns management services, handling the entire returns process from receiving returned items to restocking or disposing of them as required.

- Efficient order processing: Orders are automated, meaning they get processed as soon as they are received and accepted. Once accepted, the order is prepared to be shipped out.

- Reliable shipping and distribution: Cencora partners with leading carriers to offer reliable and cost-effective shipping options. Our robust distribution network ensures that deliveries are timely and reach customers in excellent condition.

- Scalable storage solutions: Cencora offers flexible and scalable storage solutions that can grow with your business. Whether you're a small startup or an established enterprise, ICS can accommodate your warehousing needs without compromising on efficiency.

- Strategically located warehouses: Cencora operates a network of strategically located warehouses across the world to ensure quick and efficient distribution. This network allows businesses to store products closer to their customer base, reducing shipping times and costs.

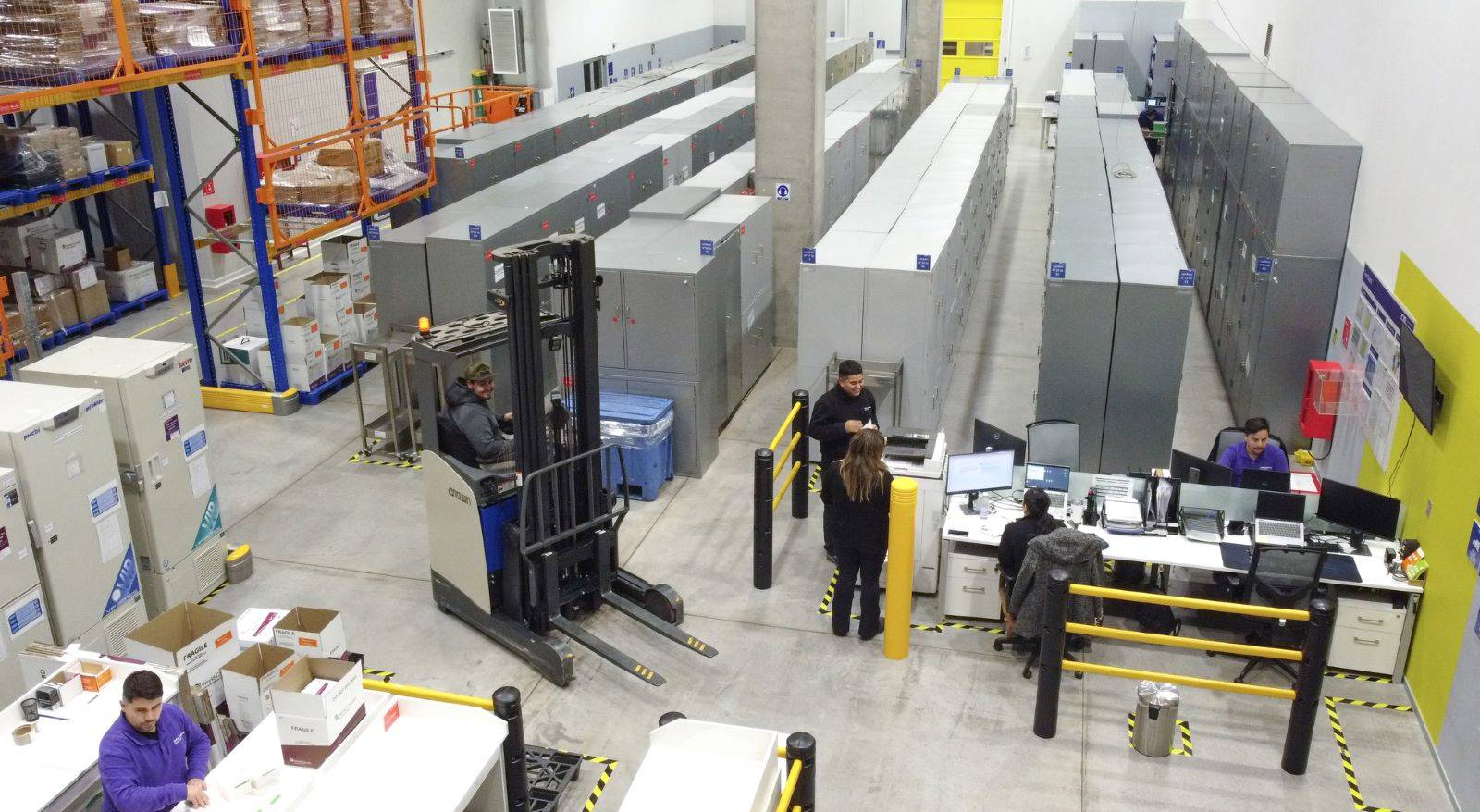

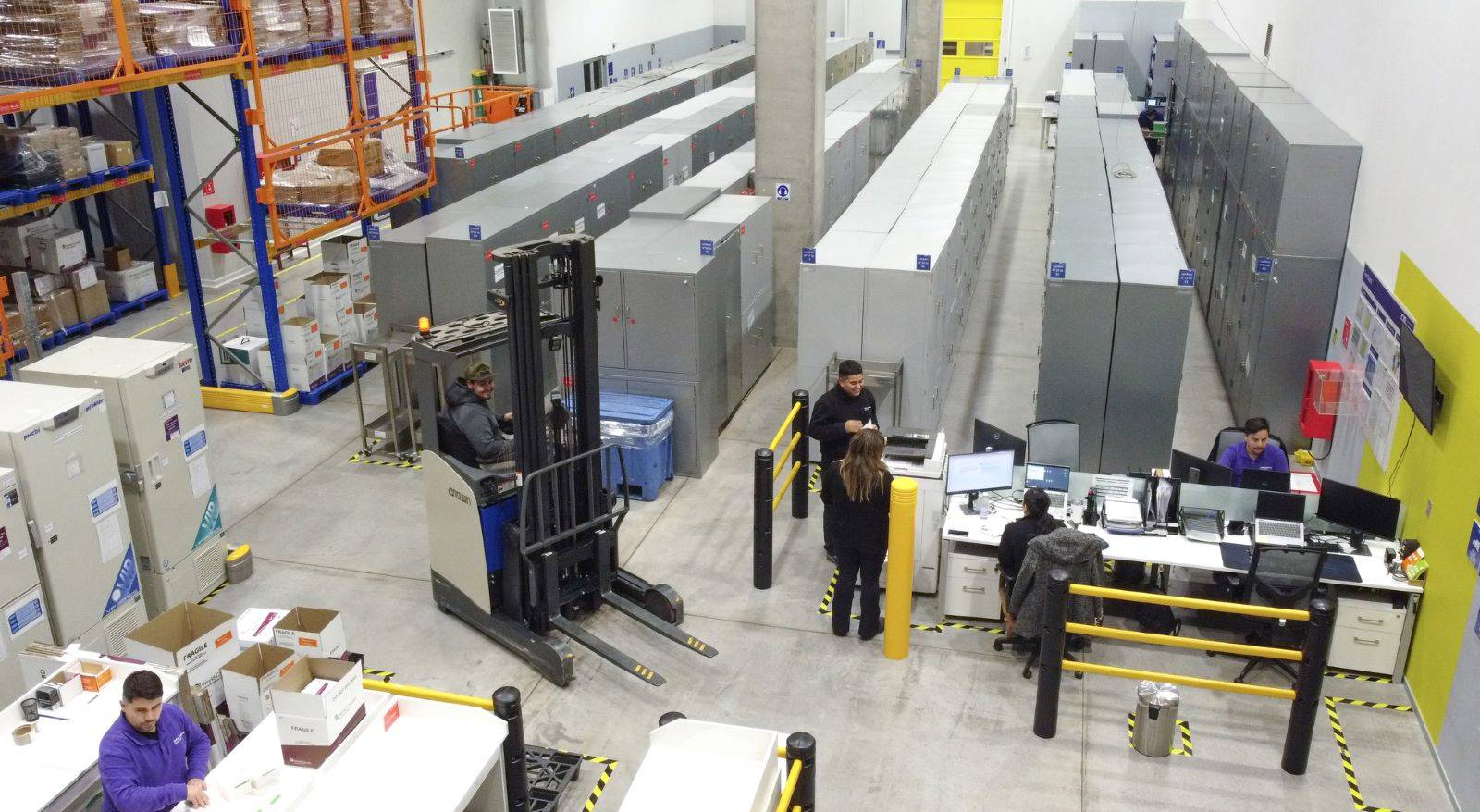

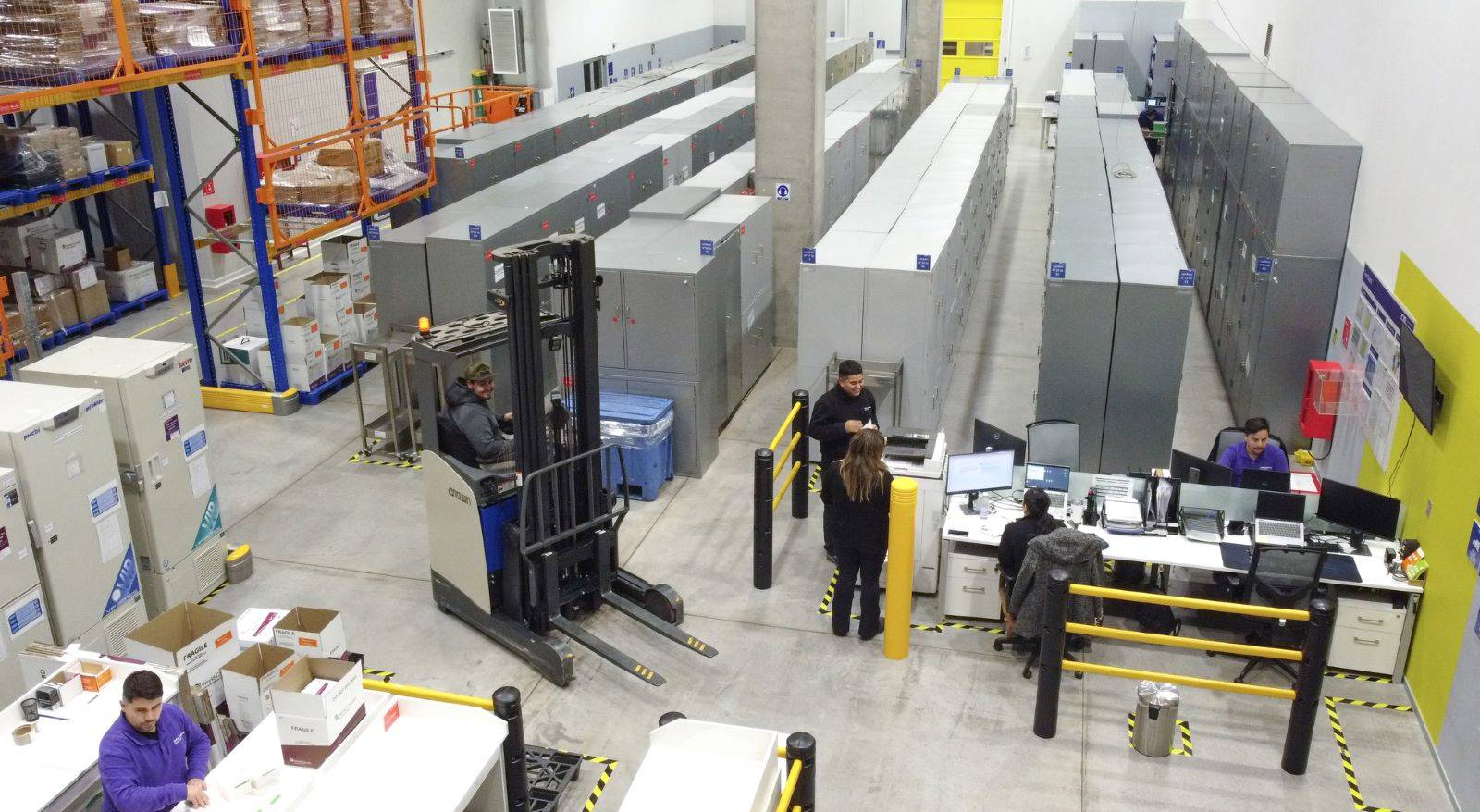

How is a warehouse used in 3rd party logistics?

Key roles of warehouses in 3PL:

Day-to-day tasks of warehouse staff:

- Warehouse staff inspect and record incoming shipments for accuracy

- Staff place items in designated storage locations

- Workers locate and collect items from storage for orders

- Staff securely package items for shipping

- Employees print labels and dispatch packages for delivery

- Staff process and restock or dispose of returned items

Warehouse software requirements:

- A warehouse management system (WMS) manages all warehouse operations

- An inventory management system (IMS) tracks stock levels and SKU performance

- An order management system (OMS) handles the entire order lifecycle

- Shipping software compares rates, prints labels, and tracks shipments

Important warehouse processes:

- Ensuring that all incoming goods are accurately received and recorded

- Efficiently storing products for easy retrieval

- Quickly picking, packing, and shipping orders

- Regularly monitoring and updating stock levels

- Handling returns to maintain inventory accuracy

What are the benefits of a 3PL provider?

In the scope of pharmaceutical distribution for example, there are many benefits of 3PL logistics. Providers have specialized expertise in handling pharmaceutical products. This means compliance with industry standards and maintaining the integrity of temperature-sensitive items. Partnering with a 3PL provider allows pharmaceutical companies to gain a competitive edge, streamline their operations, and ensure the safe and efficient distribution of essential medications to patient.

What is a 3rd party logistics company?

Many people ask, "What is 3PL?" A third-party logistics (3PL) company is an outsourced service provider that manages various logistics operations for businesses. This includes tasks such as inventory management, warehousing, order fulfillment, and transportation.

3PL providers offer specialized expertise and advanced technology to ensure efficient and reliable logistics solutions.

How to choose the right 3PL partner

Scale and experience

Goal alignment and strategic guidance

Value-added services

Customer service and account management